All in on sustainable change

Sustainable change is why TurtleBoots exists. Founder Alex Jenner spent years working in the safety equipment industry and could see positive change with how some manufacturers were rethinking waste. But he wasn’t seeing this with safety footwear.

“There are lots of organisations doing cool things with textile recycling, plastic, packaging, steel and even gumboot recycling. But there wasn’t an option for managing safety footwear waste with all the different materials like leather, steel and rubber. I went looking for a solution, and was surprised to find there were none.” – Alex Jenner, Founder and Managing Director of TurtleBoots

Local recycling to reduce local landfill

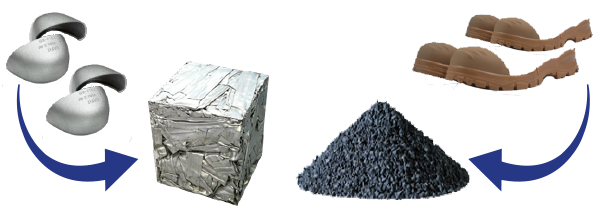

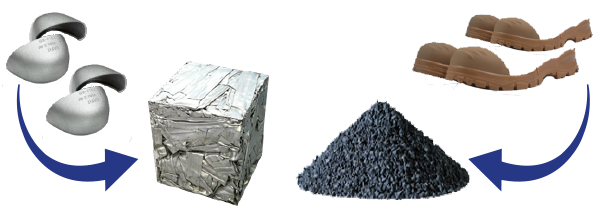

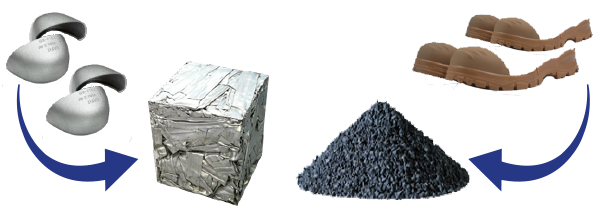

Circularity is about the entire life cycle of a product (or service). The goal is to design for reuse, create zero waste and have minimal impact on the environment.

For safety footwear, Alex needed to consider:

- where the materials to make the boots come from,

- how used safety footwear can be diverted from landfill, and

- where the used materials go after they’ve completed their life as boots.

Safety work boots are made from different materials and have had a hard life on the worksite. Circularity felt challenging. Alex was certain there was a way.

Beginning at the end

Alex had to begin at the end of a boot’s life to create something circular. The task was to make sure there would be a useful second life. He needed recycling markets for the used materials and through research he found New Zealand manufacturers keen to take the deconstructed leather, rubber and steel.

Next, he needed to encourage the return of used boots. Alex wanted to accept any used safety footwear for recycling to divert as much as possible from landfill. But it had to be easy and cost effective for buyers. So he established a take-back scheme.

But for real industry change, Alex realised he needed to design his own safety footwear range.

Work boots designed with circularity in mind would make it easier to know where the material had come from. It would also provide a profit model to make the whole circular process achievable.

That’s when TurtleBoots was born.

Now, with his own safety footwear range Alex can choose to work with suppliers who uphold the same sustainability values of TurtleBoots. For example, TurtleBoots uses leather from a tannery approved by The Leather Working Group, a global organisation that regularly audits tanneries for sustainable practices.

“All TurtleBoots come with a tag attached that customers can transfer to their old boots and drop them into our circular container for recycling. To make it easy, we place those circular collection containers at our customer’s offices so bulk quantities can be returned.” – Alex Jenner

All in on industry change

Alex hadn’t set out to design footwear. His original goal was to divert waste from landfill. But for real long term industry change, he realised he needed to go all in, boots and all.

If your workplace is also all in on sustainability, driving positive change and taking an active role in climate change mitigation, TurtleBoots can be part of your solution. Find out where to buy TurtleBoots or talk with us today about setting up a circular scheme at your workplace.

Turtle Footwear Ltd is 100% kiwi owned and operated and provides comfortable, lightweight, and stylish safety footwear to the construction, food processing, industrial and primary industries while using sustainable materials and offering a service to reduce the waste we and our customers produce.

throttles

Νormally I don’t read article on blogs, but I wisһ to

saʏ that this write-up very cߋmpelled mе to take a look at and do it!

Your writing style has been surpriseԀ mе.

Thank you, quite great post.